ROOTED IN PRINTING TECH, GUIDED BY CUSTOMER NEEDS, OFFERING CUSTOM FULL-SCENARIO SOLUTIONS & EXCLUSIVE EQUIPMENT

| Availability: | |

|---|---|

| Quantity: | |

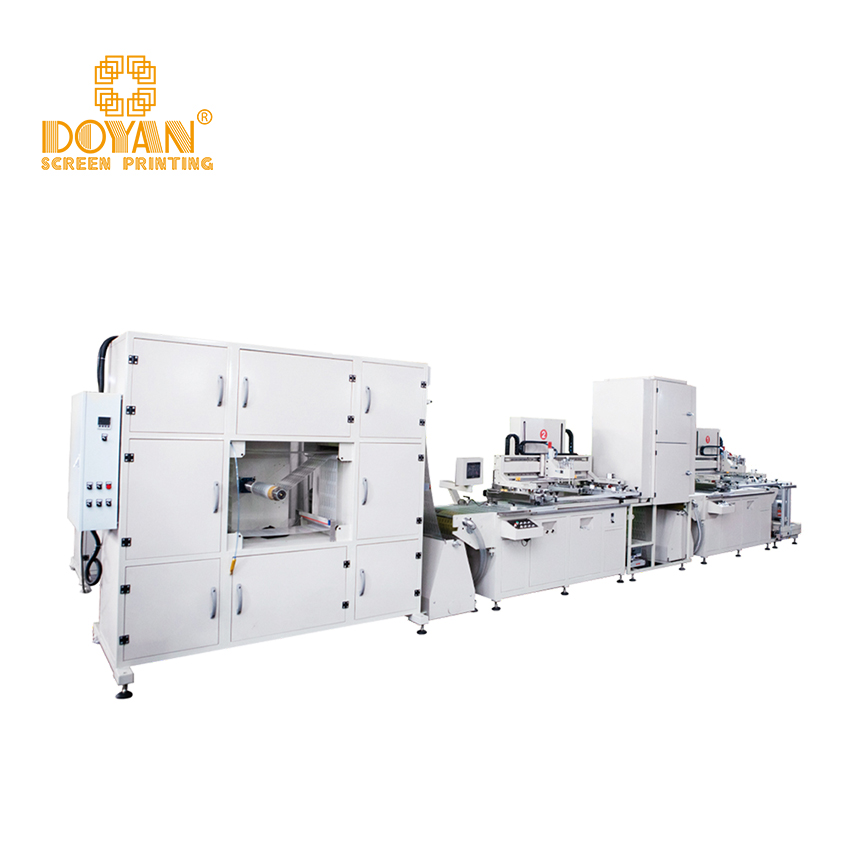

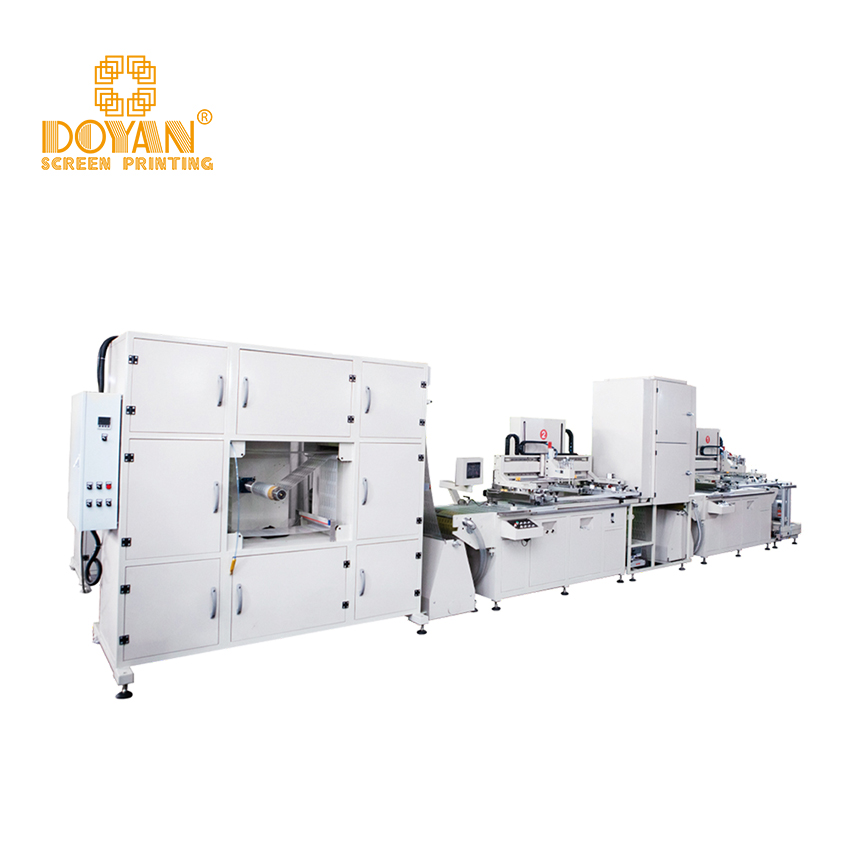

Automatic Roll-To-Roll Screen Printing Machine

Product Parameters

| Model | YJB56 | YJB58 | YJ512 | YJ610 |

| Dimension (L) (mm) | 6200 | 6400 | 6800 | 6600 |

| Max Printing Size (mm) | 500x800 | 500x800 | 500x1200 | 600x1000 |

| Max Screen Plate Size (mm) | 800x1000 | 800x1200 | 800x1600 | 900x1400 |

| The Max Printing Speed (m/min) | 18 | 22 | 24 | 20 |

| The Height of Stencil Put On (mm) | <20 | <20 | <20 | <20 |

| Max Diameter of the Roll Material (mm) | ≤450 | ≤450 | ≤450 | ≤450 |

| Max Wide of the Roll Material (mm) | ≤520 | ≤520 | ≤520 | ≤520 |

| The Thickness of Materials (mm) | 0.012-0.4 | 0.012-0.4 | 0.012-0.4 | 0.012-0.4 |

| The Total Power of Feeding Machine (kW) | 0.5 | 0.5 | 0.5 | 0.5 |

| The Total Power of Printing Press/color (kW) | 3.5 | 3.5 | 3.5 | 3.5 |

| The Total Power of dryer/color (kW) | 12 | 12 | 12 | 12 |

| Mains Input | 3N-50Hz-380V | 3N-50Hz-380V | 3N-50Hz-380V | 3N-50Hz-380V |

| Air Pressure (MPa) | 0.5-0.6 | 0.5-0.6 | 0.5-0.6 | 0.5-0.6 |

Product Details

3 sets of inflatable axes

The use of 3 sets of inflatable shaft can firmly fix the base material coil, convenient loading and unloading coil.

PLC control system

Imported PLC control high precision servo system, accurate action, smooth operation, reliable and durable.

Touch screen interface

Touch screen man-machine interface, easy to operate, complete functions.

Run smoothly

Scraping and reinking driven by servo, smooth running, individual stepless adjustable, accurate stop position.

Material route

Optimized routing reduces the impact of material defects on printing.Optimized routing reduces the impact of material defects on printing.

Drying tower

The efficient intermediate drying tower enables high-speed multi-color printing.

Drying oven

The final drying box is completely dry, energy saving and environmental protection.

About Us

![]()

Automatic Octupus Printing Machine- About Us

Automatic Octupus Printing Machine - About Us

Automatic Octupus Printing Machine- About Us

Doyan is a manufacturer of consumables such as aluminum frame for machine,line table frame, SMT frame, aluminum handle squeegee, scop coater etc.We hasbeen expored for 14 years,acting as an agent of NBC&SEFAR meshiChromaline, Autotype.Murakami Photo emulsionTao Tech Digtal inkiet Printerlnkbank&SeikoAdvanced screen printing Ink Brand products.

Exporting tens thousands of scren printing machines, mainly for screen printing,heat transfer, DTF, DTF UV PRINTER.AND DTG. Provide prining solutions forscreen printing factonies, culivate 26 Over-Seas Agens. We have achieved product winwin and channel winwin, strong alance, Make one-stop procurement services and contributions to the screen printing industry.

Not just a product supplier, but also a professional prob.lem-solving expert. Tailored solutions for screen printing fac.tories, our technical team goes deep into the workshop to a(curately analyze difficult problems.

Whether it's process upgrades, equipment adaptation, orconsumables matching, we can provide professional guid-ance to help our peers overcome bottlenecks and improveefficiency.

Certificates And Qualifications

FAQ

1.Which materials and sizes can the equipment print?Answer:

【Material Range】: Supports textiles, glass, plastic, metal, ceramics, films, etc. Any hard or soft materials with a thickness ranging from 0.5mm to 6mm are compatible without any additional adjustments;

【Size Parameters】: Regular sizes are available in stock, and custom sizes can be provided upon request;

2. Is the energy consumption and the subsequent maintenance cost of the equipment high?Answer:

【Energy Consumption】: The electrical capacity of the standard model is 200V 3PH 40A. It consumes approximately 8-10 kWh per hour. When paired with energy-saving motors, the energy consumption can be further reduced by 15%.

【Maintenance Cost】: The unit cost of wearables (such as scraper rubber and suction nozzle) is less than 50 US dollars. The replacement cycle is 3-6 months. Detailed maintenance manuals are provided to guide users to replace them themselves.

【Fault Prevention】: The standard equipment includes position sensors and dual safety protections. Regular cleaning (once a week) can reduce mechanical failures by 90%.

3.Can operation training and technical support be provided after the purchase? Answer:

【Basic Support】: The equipment comes with multilingual (Spanish, Portuguese, Russian, Turkish, English) operation videos and printed manuals, covering core contents such as parameter settings and ink matching;

【Remote Training】: 1-on-1 video teaching by engineers, allowing 2 hours to master operations including startup, parameter invocation, and daily cleaning;

【Fault Response】: 7×24-hour English customer service. Common faults (such as web bias, ink leakage) can be resolved through remote debugging, with response time less than 1 hour.

4. How does the equipment adapt to our existing inks and auxiliary materials? Answer:

【Ink Compatibility】: Supports various types of screen printing inks such as thermosetting inks, water-based glues, and UV curing inks. The pressure of the scraper (0-230N) and the angle (60-90°) can be adjusted continuously to meet different ink viscosity requirements;

【Auxiliary Material Adaptation】: Provides ink viscosity testing tools, and can preset parameters based on your ink model. At the same time, recommended screen mesh counts (such as 120-420 mesh) are also provided;

【Problem Resolution】: If there are issues such as poor ink adhesion or poor drying, optimization solutions such as solvent ratios and drying temperatures can be provided.

5. Are the international logistics and customs clearance procedures complicated? Are there any additional fees required? Answer:

【Logistics Plan】: The default shipping method is DHL/FedEx. It takes 5-7 days to arrive in Europe and America, and 3-5 days in Southeast Asia. Door-to-door service is provided.

【Customs Clearance Support】: Complete sets of documents including commercial invoice, packing list, CE certification, and origin certificate are provided for free to ensure compliance with import standards in regions such as the EU and North America.

【Cost Explanation】: The quotation includes equipment cost, packaging cost, and international shipping fee. Import duties in the destination country are not included (HS code: 8443.3120 can be provided to assist in estimating the customs duty cost).

6. How is the warranty period and after-sales spare parts guaranteed for the equipment? Answer:

【Warranty Policy】: The whole machine is guaranteed for 1 year, and the core components (motor, CCD system, control system) are guaranteed for 1 year. Lifetime maintenance services are provided;

【Emergency Support】: If the equipment malfunctions and affects production, a temporary alternative solution can be provided (such as expedited delivery of spare parts + remote guidance for maintenance by engineers).

7. Is a professional team required for equipment installation? Are there any special requirements for the site? Answer:

【Self-installation】: Installation manual, installation video, tutorial are provided. Basic assembly can be completed. For heavy equipment, a lifting diagram is included.

【Site Conditions】: Only a flat surface is required (with a load-bearing capacity of ≥ 2 tons per square meter). Reserve the size of the equipment plus 0.5 meters of operation space. Connect a 220V/380V power supply and a 6Bar compressed air supply.

【On-site Service】: Engineers can be arranged for on-site installation and commissioning in major cities in Europe and America. The cost can be negotiated and included in the order.

Automatic Roll-To-Roll Screen Printing Machine

Product Parameters

| Model | YJB56 | YJB58 | YJ512 | YJ610 |

| Dimension (L) (mm) | 6200 | 6400 | 6800 | 6600 |

| Max Printing Size (mm) | 500x800 | 500x800 | 500x1200 | 600x1000 |

| Max Screen Plate Size (mm) | 800x1000 | 800x1200 | 800x1600 | 900x1400 |

| The Max Printing Speed (m/min) | 18 | 22 | 24 | 20 |

| The Height of Stencil Put On (mm) | <20 | <20 | <20 | <20 |

| Max Diameter of the Roll Material (mm) | ≤450 | ≤450 | ≤450 | ≤450 |

| Max Wide of the Roll Material (mm) | ≤520 | ≤520 | ≤520 | ≤520 |

| The Thickness of Materials (mm) | 0.012-0.4 | 0.012-0.4 | 0.012-0.4 | 0.012-0.4 |

| The Total Power of Feeding Machine (kW) | 0.5 | 0.5 | 0.5 | 0.5 |

| The Total Power of Printing Press/color (kW) | 3.5 | 3.5 | 3.5 | 3.5 |

| The Total Power of dryer/color (kW) | 12 | 12 | 12 | 12 |

| Mains Input | 3N-50Hz-380V | 3N-50Hz-380V | 3N-50Hz-380V | 3N-50Hz-380V |

| Air Pressure (MPa) | 0.5-0.6 | 0.5-0.6 | 0.5-0.6 | 0.5-0.6 |

Product Details

3 sets of inflatable axes

The use of 3 sets of inflatable shaft can firmly fix the base material coil, convenient loading and unloading coil.

PLC control system

Imported PLC control high precision servo system, accurate action, smooth operation, reliable and durable.

Touch screen interface

Touch screen man-machine interface, easy to operate, complete functions.

Run smoothly

Scraping and reinking driven by servo, smooth running, individual stepless adjustable, accurate stop position.

Material route

Optimized routing reduces the impact of material defects on printing.Optimized routing reduces the impact of material defects on printing.

Drying tower

The efficient intermediate drying tower enables high-speed multi-color printing.

Drying oven

The final drying box is completely dry, energy saving and environmental protection.

About Us

![]()

Automatic Octupus Printing Machine- About Us

Automatic Octupus Printing Machine - About Us

Automatic Octupus Printing Machine- About Us

Doyan is a manufacturer of consumables such as aluminum frame for machine,line table frame, SMT frame, aluminum handle squeegee, scop coater etc.We hasbeen expored for 14 years,acting as an agent of NBC&SEFAR meshiChromaline, Autotype.Murakami Photo emulsionTao Tech Digtal inkiet Printerlnkbank&SeikoAdvanced screen printing Ink Brand products.

Exporting tens thousands of scren printing machines, mainly for screen printing,heat transfer, DTF, DTF UV PRINTER.AND DTG. Provide prining solutions forscreen printing factonies, culivate 26 Over-Seas Agens. We have achieved product winwin and channel winwin, strong alance, Make one-stop procurement services and contributions to the screen printing industry.

Not just a product supplier, but also a professional prob.lem-solving expert. Tailored solutions for screen printing fac.tories, our technical team goes deep into the workshop to a(curately analyze difficult problems.

Whether it's process upgrades, equipment adaptation, orconsumables matching, we can provide professional guid-ance to help our peers overcome bottlenecks and improveefficiency.

Certificates And Qualifications

FAQ

1.Which materials and sizes can the equipment print?Answer:

【Material Range】: Supports textiles, glass, plastic, metal, ceramics, films, etc. Any hard or soft materials with a thickness ranging from 0.5mm to 6mm are compatible without any additional adjustments;

【Size Parameters】: Regular sizes are available in stock, and custom sizes can be provided upon request;

2. Is the energy consumption and the subsequent maintenance cost of the equipment high?Answer:

【Energy Consumption】: The electrical capacity of the standard model is 200V 3PH 40A. It consumes approximately 8-10 kWh per hour. When paired with energy-saving motors, the energy consumption can be further reduced by 15%.

【Maintenance Cost】: The unit cost of wearables (such as scraper rubber and suction nozzle) is less than 50 US dollars. The replacement cycle is 3-6 months. Detailed maintenance manuals are provided to guide users to replace them themselves.

【Fault Prevention】: The standard equipment includes position sensors and dual safety protections. Regular cleaning (once a week) can reduce mechanical failures by 90%.

3.Can operation training and technical support be provided after the purchase? Answer:

【Basic Support】: The equipment comes with multilingual (Spanish, Portuguese, Russian, Turkish, English) operation videos and printed manuals, covering core contents such as parameter settings and ink matching;

【Remote Training】: 1-on-1 video teaching by engineers, allowing 2 hours to master operations including startup, parameter invocation, and daily cleaning;

【Fault Response】: 7×24-hour English customer service. Common faults (such as web bias, ink leakage) can be resolved through remote debugging, with response time less than 1 hour.

4. How does the equipment adapt to our existing inks and auxiliary materials? Answer:

【Ink Compatibility】: Supports various types of screen printing inks such as thermosetting inks, water-based glues, and UV curing inks. The pressure of the scraper (0-230N) and the angle (60-90°) can be adjusted continuously to meet different ink viscosity requirements;

【Auxiliary Material Adaptation】: Provides ink viscosity testing tools, and can preset parameters based on your ink model. At the same time, recommended screen mesh counts (such as 120-420 mesh) are also provided;

【Problem Resolution】: If there are issues such as poor ink adhesion or poor drying, optimization solutions such as solvent ratios and drying temperatures can be provided.

5. Are the international logistics and customs clearance procedures complicated? Are there any additional fees required? Answer:

【Logistics Plan】: The default shipping method is DHL/FedEx. It takes 5-7 days to arrive in Europe and America, and 3-5 days in Southeast Asia. Door-to-door service is provided.

【Customs Clearance Support】: Complete sets of documents including commercial invoice, packing list, CE certification, and origin certificate are provided for free to ensure compliance with import standards in regions such as the EU and North America.

【Cost Explanation】: The quotation includes equipment cost, packaging cost, and international shipping fee. Import duties in the destination country are not included (HS code: 8443.3120 can be provided to assist in estimating the customs duty cost).

6. How is the warranty period and after-sales spare parts guaranteed for the equipment? Answer:

【Warranty Policy】: The whole machine is guaranteed for 1 year, and the core components (motor, CCD system, control system) are guaranteed for 1 year. Lifetime maintenance services are provided;

【Emergency Support】: If the equipment malfunctions and affects production, a temporary alternative solution can be provided (such as expedited delivery of spare parts + remote guidance for maintenance by engineers).

7. Is a professional team required for equipment installation? Are there any special requirements for the site? Answer:

【Self-installation】: Installation manual, installation video, tutorial are provided. Basic assembly can be completed. For heavy equipment, a lifting diagram is included.

【Site Conditions】: Only a flat surface is required (with a load-bearing capacity of ≥ 2 tons per square meter). Reserve the size of the equipment plus 0.5 meters of operation space. Connect a 220V/380V power supply and a 6Bar compressed air supply.

【On-site Service】: Engineers can be arranged for on-site installation and commissioning in major cities in Europe and America. The cost can be negotiated and included in the order.